CALL FOR CONSULTATION

+91 8130425942

care@gscientific.in

WORKING HOURS

Mon-Fri: 9:30am to 5:30pm

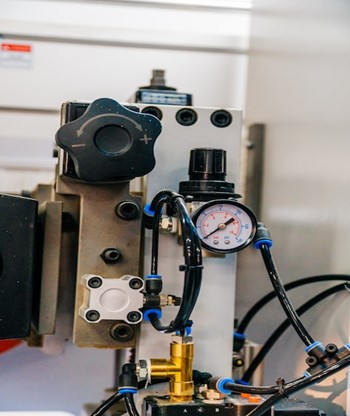

We specialize in designing and manufacturing customizable testing equipment tailored to meet your unique needs.

We understand that every project is different.

That’s why we offer a comprehensive customization service that allows you to tailor our products to your specific requirements.

Whether you need modifications to existing models or a completely bespoke solution, our flexible approach ensures that your unique challenges are met with precision and efficiency.

A life cycle test apparatus is used to simulate and evaluate the durability, performance, and longevity of a product or material under conditions that mimic real-world usage over time. The apparatus is designed to apply repeated mechanical, thermal, electrical, or environmental stresses to determine how long a product can function before it fails. Life cycle testing is critical for assessing the reliability of products, identifying potential failure points, and ensuring they meet industry standards and customer expectations for longevity.

Mechanical Life Cycle Testing:

- Fatigue Testing Machines: Apply repetitive loads or stresses to determine how long a material or product can endure cyclic mechanical forces. Examples include testing hinges, bearings, or structural components.

- Tensile, Compression, and Bending Testers: Evaluate how well a product withstands repetitive mechanical stresses, such as bending, pulling, or pushing.

A Durability Test apparatus is used to simulate the wear and tear, stress, and environmental factors a product or material might encounter over its lifetime to assess its long-term performance, strength, and reliability. Durability testing is essential for understanding how a product will behave under real-world conditions, ensuring it meets safety and quality standards before going to market. Durability tests can be mechanical, environmental, chemical, or thermal, depending on the product’s intended use.

Mechanical Durability Test Apparatus:

- Fatigue Test Machines: Simulate repeated load, stress, or strain on a product. Used to test components like springs, hinges, or fasteners that are subject to cyclic loading.

- Wear and Abrasion Testers: Evaluate the resistance of materials, such as textiles, plastics, or coatings, to friction and surface wear. The apparatus rubs or drags a material against a standardized surface for a specific number of cycles.

- Impact Testers: Test the ability of a product to withstand sudden forces or impacts. Common in industries like automotive, electronics, and construction to simulate drops, hits, or collisions.

An Endurance Test apparatus is designed to evaluate a product or material’s ability to withstand repeated or prolonged stress, strain, or environmental conditions over time, helping to determine its longevity and reliability. Endurance testing subjects the product to conditions that simulate long-term use, and it’s commonly used for components in the automotive, aerospace, electronics, construction, and medical industries.

Mechanical Endurance Test Apparatus:

- Fatigue Test Machines: Designed to apply cyclic loading to materials or components, testing their resistance to repeated stress. These are commonly used to test mechanical parts like gears, springs, or hinges.

- Tensile, Compression, and Bending Testers: Test materials and products under repetitive tensile (stretching), compression (pushing), or bending forces. These testers are often used for materials like metals, plastics, and composites.

- Rotational Fatigue Testers: Used to test rotating components such as shafts, bearings, and joints that experience cyclic rotational loads during use.

- Wear and Tear Testers: Simulate the repetitive wear a surface or product endures over time, such as textile wear, plastic degradation, or the abrasion of coatings.

CALL FOR CONSULTATION

+91 8130425942

care@gscientific.in

LOCATION

GF, Plot 63, Kh. No. 46/4,

Dharampura Colony, A-1,

Najafgarh, New Delhi - 110043