Fire Testing Equipment Manufacturing

CALL FOR CONSULTATION

+91 8130425942

care@gscientific.in

WORKING HOURS

Mon-Fri: 9:30am to 5:30pm

Reaction to fire testing includes the combustibility and flammability of a material i.e. its contribution to fire development and spread of flame, ignitability etc.

This also includes Heat Release, Smoke Density & Toxicity with Spread of Flame tests for Railway Vehicles.

Major Tests are :

• Non-Combustibility Test

• Fire Propagation Test

• Surface Spread of Flame

• Surface Burning Characteristics

• Cone Calorimeter

• Smoke Density Chamber

• Lateral Spread of Flame

• Burning Behavior of Floorings

• Limiting Oxygen Index

• Flammability Test

The Non-Combustibility Apparatus, as per ISO :1.:1.82, is utilized to assess the non-combustibility performance of building and railway materials at a temperature of 750°C in a furnace.

During the Non-Combustibility Test, a test specimen {with a diameter of 45 mm and a height of 50 mm) is placed into a stabilized furnace at 750°C. The temperatures of the furnace, the surface, and the center of the specimen are measured. Additionally, the flaming duration and mass loss are recorded.

Non-Combustibility Test is widely used to assess the flammability performance class of materials, such as EN 13501-1, EN 45545-2, DIN 4102, IMO FTP Code, etc.

Non-Combustibility Apparatus consists of:

• Special furnace support with Teflon finish for anti-corrosion.

• A refractory tube furnace, the operating temperature resisting over 1000 degrees.

• The heating element is replaceable and easy to maintain.

• The furnace conforms to various international standards.

• Automated furnace temperature control system, provides a fast temperature stabilization program and calibration stabilization program.

• Standard test program and Individual furnace temperature calibration program.

• Stainless steel made sample holder.

• Fast specimen holder loading fixturing.

• Data acquisition system, record frequency once per second.

• Temperature resolution @ 0.1 Degrees Celsius & timing resolution @ 0.1sec.

• Report management and export.

Test Method: ISO 1182, BS 476-4, ASTM E136, IS 3808

The Fire Propagation Apparatus provides a comparative measure of the contribution to the growth of fire made by an essentially flat material, the result usually expressed as a fire propagation index. It’s generally used to assess the performance of the internal wall andceiling linings.

Fire Propagation Apparatus consists of :

• Stainless steel made combustion chamber structure and support.

• Standard stainless steel made chimney and cowl assembly, with black painting for less heat reflection.

• 3 Kinds of sample holders for various thicknesses of materials, easy-to load specimens.

• 2 Thermocouple holders on the side of the cowl, fast mounting design.

• 2 heating elements, each of 1000W rating.

• Intelligent PlD power controller with a feedback loop

for accurate control of electric heating elements.

• Stainless steel made gas burner.

• Gas supply control system includes a manometer, gas flowmeter, gas pressure regulating device, a gas control valves.

• Visualized wattmeter for fast monitoring of the power output of the heating elements.

• Promoted software, function includes

auto-calibration routine, automated load the calibration data, auto standard test routine, test report export and storage.

Test Method : BS 476 Part 6

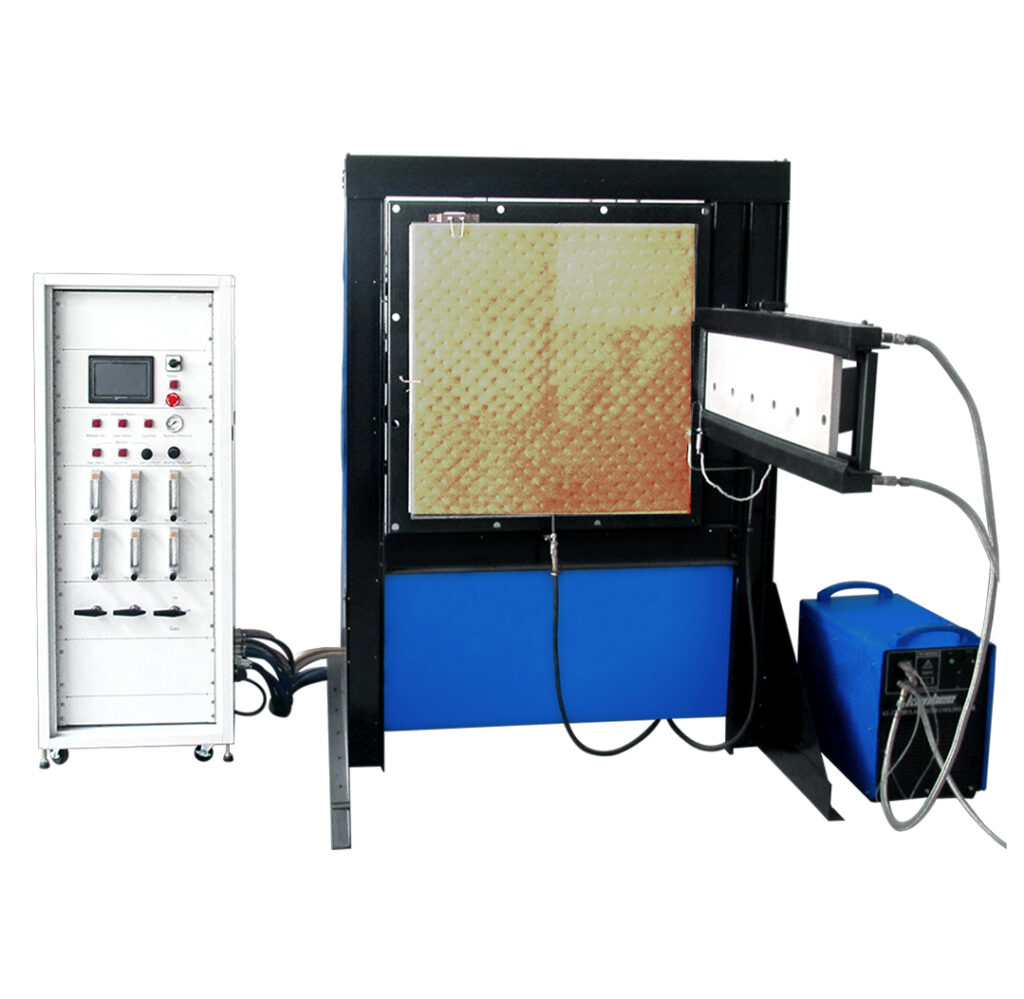

3C. Surface Spread of Flame Test Apparatus

Surface Spread of Flame Test Apparatus, in accordance with BS 476 part 7, is used to measure the lateral spread of flame along the surface of a product in the vertical orientation exposed to a particular radiant panel. It provides data for assessing the potential fire hazard of a product in particular conditions, such as the product used in the walls and ceilings.

It is used for determining the classification of building material products when exposed to a standardized heat source. The test is widely used for evaluating materials in building construction to ensure fire safety compliance.

Test Method : BS 476 Part 7, IS 12777

Surface burning characteristics test: This test measures the surface burning characteristics of building materials. particularly those used for wall andceiling finishes. by assessing their flame spread index and smoke development.

The purpose of the test is to assess the relative burning behaviour of the material being tested by measuring the spread of flames across its surface and the amount of smoke produced when exposed to a controlled fire. This evaluation provides a basis for comparing the surface burning characteristics of different materials. without considering all the specific conditions that might influence their behaviour in actual end-use scenarios.

A sample of the material is placed in a test chamber and exposed to a controlled flame.

The Test Measures:

- Flame Spread Index (FSI): The rate at which the flame spreads across the surface of the

- Smoke Developed Index (SDI): The amount of smoke produced during the test. Classification:

Materials are classified based on their performance in the test. The results categorize materials into different classes according to their surface spread characteristics. which can influence building regulations and safety codes and classification of products: Class 1. Class 2 etc.

Test Methods: ASTM E 84, UL 723

3E. CONE CALORIMETER (ISO 5660-1)

The Cone Calorimeter is a specialized instrument used for measuring the flammability and heat release properties of materials under controlled conditions. It consists of a heat source (often an electric heater), a sample holder, and instrumentation to measure various parameters during the test.

Our Cone Calorimeters are engineered with precision and adhere to industry

standards, ensuring accurate and reliable measurement of critical fire behaviour

parameters. With our advanced equipment, you can assess the flammability and

fire performance of various materials and products.

Key features of the Cone Calorimeter include:

1. Heat Flux Measurement:

It measures the heat flux (energy transfer rate per unit area) applied to the sample, which simulates real-world fire conditions.

2. Temperature Measurement:

Sensors monitor the temperature rise of the sample and surrounding environment.

3. Gas Analysis:

Instruments analyze the gases produced during combustion, providing insights into the combustion products and their toxicity.

4. Mass Loss Measurement:

Monitors the mass loss of the sample as it burns, helping to assess fire spread characteristics.

5. Ignition Time:

Determines the time it takes for the material to ignite under specified conditions.

6. Data Acquisition System:

Collects and records real-time data throughout the test, allowing for detailed analysis of fire behaviour.

7. Customizable Test Parameters:

The calibrators feature adjustable test parameters such as heat flux, sample size, and specimen orientation. This flexibility allows for customized testing conditions to meet specific research or industry requirements.

Test Methods: ISO 5660-1

A Smoke Density Chamber is a specialized apparatus designed to measure the optical density of smoke emitted during combustion. It provides quantitative data on the smoke produced by materials when exposed to heat or flame. Key features of Smoke Density Chambers include:

Our test chambers are designed to accurately measure and analyse smoke density

during fire testing, providing critical insights into the composition and potential

health hazards associated with smoke emissions.

Key Features

1.Optical Measurement:

Utilizes optical sensors or photometric techniques to measure the density of smoke particles in the chamber.

2. Airflow Control:

Allows for controlled airflow to simulate realistic fire scenarios and ensure uniform distribution of smoke within the chamber.

3. Data Acquisition System:

Collects real-time data on smoke density, enabling accurate measurement and analysis.

4. Comprehensive Smoke Composition Analysis:

Our test chambers provide detailed analysis of smoke composition, including the identification and measurement of various combustion byproducts and hazardous compounds. This information helps in assessing the toxicity and potential health risks associated with the smoke.

5. Wide Range of Detection:

The Smoke Density Test Chambers with FTIR are capable of detecting a wide range of gases and particulates present in smoke, such as carbon dioxide, carbon monoxide, hydrogen cyanide, and other harmful compounds. This comprehensive detection capability ensures accurate assessment of smoke composition.

Test Method : ISO 5659-2

The Lateral Spread of Flame Tester, in accordance with ISO 5658-2, is designed to assess the flame spread characteristics of materials, particularly in building and transportation industries. Here is an overview of its key features and applications:

Key Features

Flexible Test Parameters:

The Lateral Flame Spread Testers feature adjustable test parameters such as flame ignition time, sample size, and specimen orientation. This flexibility enables customized testing conditions to meet specific research or industry requirements

Enclosed Chamber:

Conducts tests in an enclosed chamber to ensure containment and accuracy.

Ventilation:

Includes proper ventilation systems for safety and test integrity.

Test Method : ISO 5658-2

Burning behaviour of floorings test: The standard is designed to measure the critical radiant flux and other characteristics of floor coverings when exposed to a defined heat source, helping to assess their fire performance.

The burning behaviour of floorings test apparatus is designed to evaluate how flooring materials react when exposed to fire. This apparatus is typically used to assess flame spread, smoke development, and the potential for heat release, specifically for flooring materials, in order to determine their safety and compliance with fire regulations. These tests are crucial for ensuring that flooring materials do not contribute significantly to the spread of fire in buildings.

Parameters Measured:

- Ignition Time: The time taken for the material to ignite when exposed to the flame.

- Critical Radiant Flux Measurement: The minimum heat flux required to sustain burning is determined.

Test Methods: ISO 9239-1

Limited Oxygen Index test: The standard aims to assess the fire resistance of materials by determining the oxygen concentration required to sustain combustion. This is critical for understanding a material’s behavior in fire scenarios.

It is used to determine the minimum concentration of oxygen, expressed as a percentage, that is required to support the combustion of a material under specified test conditions. This test is widely used for evaluating the flammability of materials, particularly polymers and textiles, by assessing how much oxygen is needed for the material to continue burning.

Parameters Measured:

- Limited Oxygen Index (LOI): Expressed as a percentage, this value indicates the minimum oxygen concentration needed to sustain combustion. Higher LOI values indicate better fire resistance.

Test Methods: ISO 4589-2

Flammability test: Flammability tests are essential for assessing how materials behave when exposed to fire, providing crucial data for fire safety and compliance with building codes. These tests evaluate the ability of materials to ignite, burn, and sustain combustion under controlled conditions.

Flammability tests are applicable in various industries, including:

- Building and construction (e.g., insulation, flooring)

- Textiles and upholstery

- Automotive and aerospace materials

- Electrical and electronic products

Test method/standards involved in EN 13501-1

| EN 13823 | Reaction to fire tests for building products — Building products excluding floorings exposed to the thermal attack by a single burning item. |

| EN ISO 1182 | Reaction to fire tests for building products — Non-combustibility test. |

| EN ISO 1716 | Reaction to fire tests for building products — Determination of the gross heat of combustion (calorific value). |

| EN ISO 9239-1 | Reaction to fire tests for floorings — Part 1: Determination of the burning behavior using a radiant heat source. |

| EN ISO 11925-2 | Reaction to fire tests — Ignitability of building products subjected to direct impingement of flame — Part 2: Single-flame source test. |

CALL FOR CONSULTATION

+91 8130425942

care@gscientific.in

LOCATION

GF, Plot 63, Kh. No. 46/4,

Dharampura Colony, A-1,

Najafgarh, New Delhi - 110043